Today as usual began with a ride to get out of the traffic of Chiang Mai. We went on a variety of roads, like this highway with no shoulder . . .

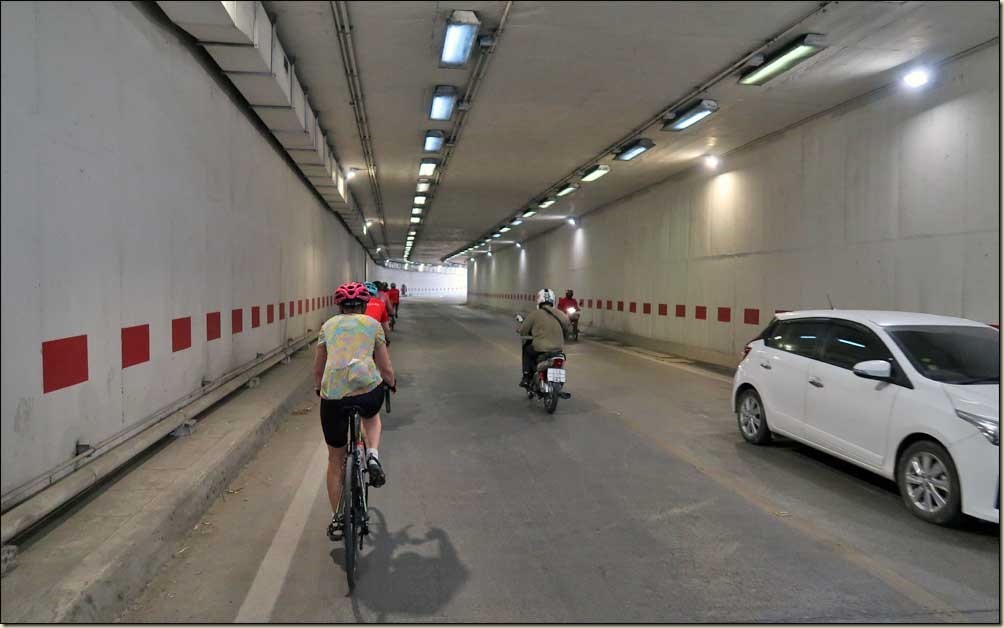

. . . to a tunnel . . .

. . . to a quiet road like this . . .

. . . to a nice path with no traffic to speak of . . .

. . . to a dirt path!! We were in a mix of terrain, from agricultural fields (rice, tobacco) to small towns.

Always nearby were the two trusty Spice Roads vans driven by Mr. Pree and Mr. Rin.

Our first cultural stop was at the umbrella market where umbrellas are made from paper in an old style way, brought originally from China.

The grounds were lovely with flowers such as this.

Everything is hand made. Here a man works on a lathe to make umbrella handles out of mulberry wood.

How long did it take him to turn all of these?!

The umbrellas are made of paper.

First the mulberry bark is soaked, then pounded to break up the fibers. Then it goes into the big vat. MJ might not have a future at the paper mill!

See MJ doing her best at smashing pulp here.

The big vat is stirred with a stick, then these wooden frames are swirled around in the water to get enough paper product on them; then they are dried.

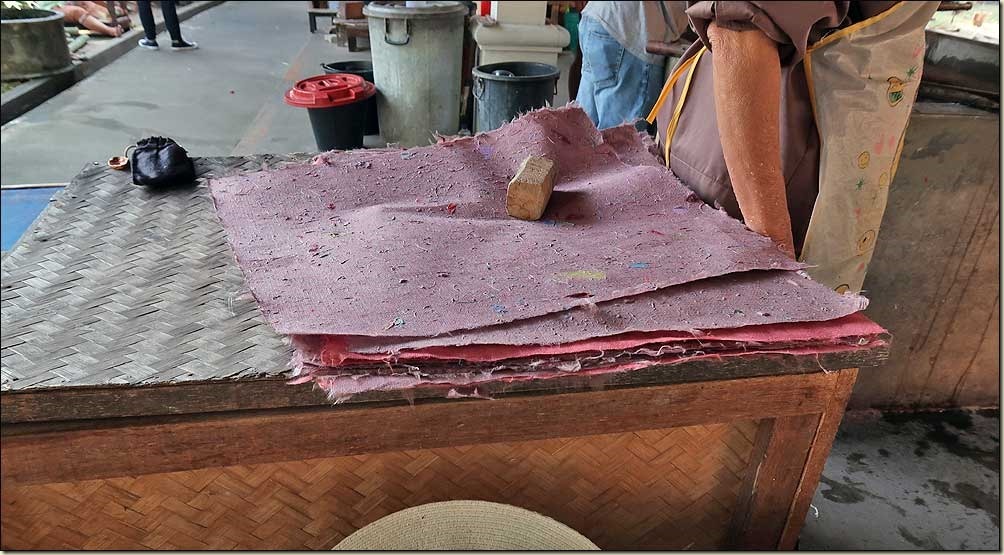

Finished paper in rough form, prior to finishing and dying.

The structural components of the umbrella workings are made of bamboo. First the bamboo exterior is peeled off. We learned that the workers make about $10 a day. Many are farmers and this is their quiet time, and otherwise they would not have work. Others were older workers with no other employment.

She smooths the edges of the bamboo chunk.

Many different tools are used to make smaller and smaller components.

Protection from the sharp knife for her finger, thank goodness!

Final products, or flitches, ready to be make into umbrellas of all sizes!

He is drilling holes into the inner workings of an umbrella….

… with a handmade drill!

Colorful umbrellas drying.

Employees were having fun which was great to see!

Then we passed through the painting area…where workers were happy to paint personal items. MJ went for butterflies and flowers on her biking shorts. Acrylic, not supposed to wash out.

She worked in a fast and focused manner.

Final product includes glitter!

Barb opted to have a Thai elephant painted on her cell phone.

We stopped at a temple for a photo op and a snack break.

Mmmmm! On the far right are yummy sticky rice packets with banana, or sweet potato, or beans inside. In addition to the fruit and bars, we had coconut pastries and boiled peanuts.

Next cultural stop was at shop that embossed aluminum.

Monica considered adding a tiara to her helmet!

This woman was adding detail to products destined for Laos.

See Tap Tap Tap movie here.

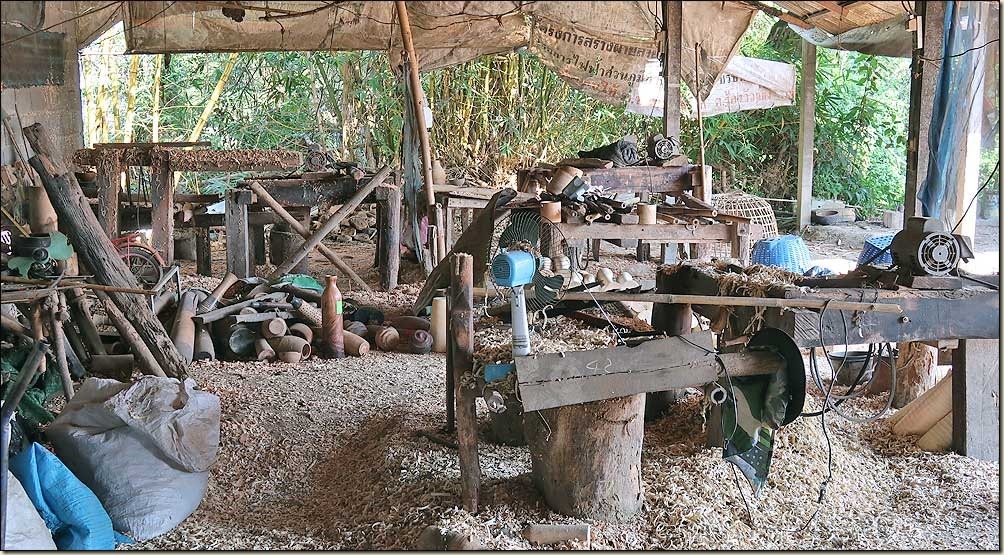

Cultural stop number three was a woodworkng shop using mango wood. Here is the raw product ready for shaping.

OSHA would have a field day at this workplace! Big lathes are used to turn the wood. Some turned products are in the background.

Big lathe that has seen better days.

The turned products, here bowls and vases, are smoked in a giant smoker. They smelled good, like bacon and campfires!

The giant smokers.

Woodie had stopped here with a group last year, and the owners had a one story house. They have added a second story, so the wood bowl and vase business must be good!

Under each basket at the shop was an agitated rooster ready to fight. We were told they were worth as much as $3000 per bird!

We bicycled on through towns and farms until we came to the San Khamphaeng Hot Springs Resort, our destination. The gang into a big discussion about past bike tours, and used the map on Tom’s jersey for reference!

We had a nice lunch, and MJ finished it up with ice cream! It was to help cool down after enjoying northern Thai pork sausage. The waitress said “not very spicy.”

The decision was made to van back to Chaing Mai due to the time of day, heat, and Friday afternoon traffic. All 12 bikes and 12 riders fit in two vans.

Bikes, bananas, and fresh cold water! What more do we need?