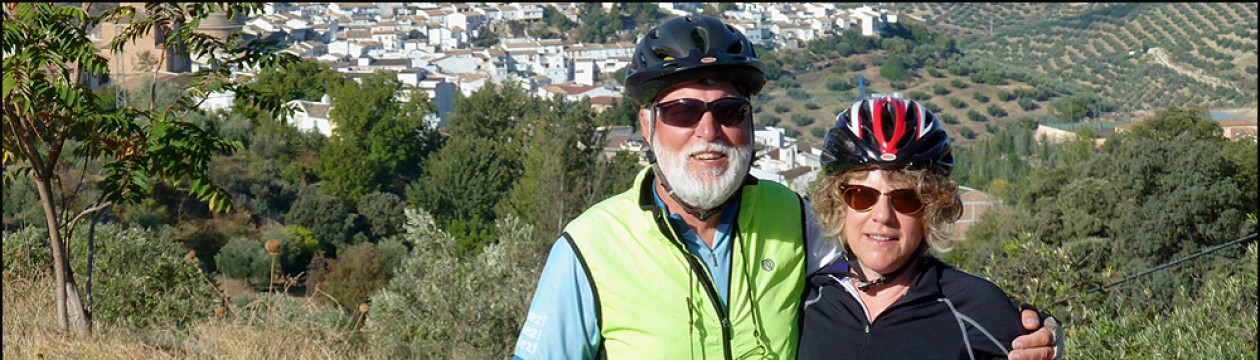

One project I have e been putting off is making a new bracket for my See.Sense bicycle lights, deemed the most intelligent bicycle light on the market, more intelligent than me, as you will probably agree with after you get done reading this.

See.Sense is Kickstarter endeavor that made good and is now selling their lights worldwide. The lights have a VERY large lumen output, are a fantastic light, and can be seen for over a mile away!

Since version 1.0, newer models have a feature that senses movement. Once the bike stops for more than 3 minutes, the flasher goes into standby mode and resumes flashing once the bike starts moving again. Helps save battery power which could be an issue during the long riding days we will have on the Southern Tier. The company offers a free firmware update to facilitate the new upgrades so I sent it off to Ireland, the location of the company headquarters. Problem is with the transit time, over and back, I will already be riding before they are returned. My bride will forward the lights to me, USPS, once they are received at our base of operations!

The back facing light is made to mount on the seat tube. I have my tube repair kit hanging from the bottom of the seat and will have the Arkel tail-rider pannier on Connie’s rear rack, so the seat tube mounting position is not an option.

Thus the need to fabricate a new bracket for the back of the rack!

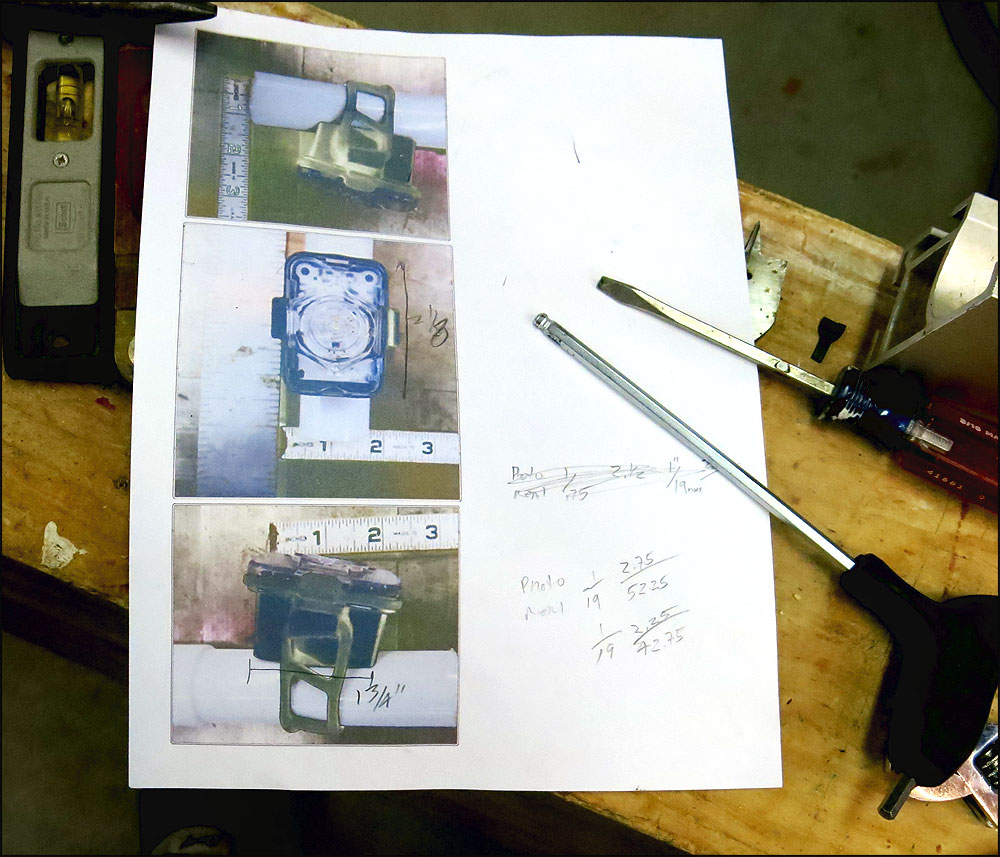

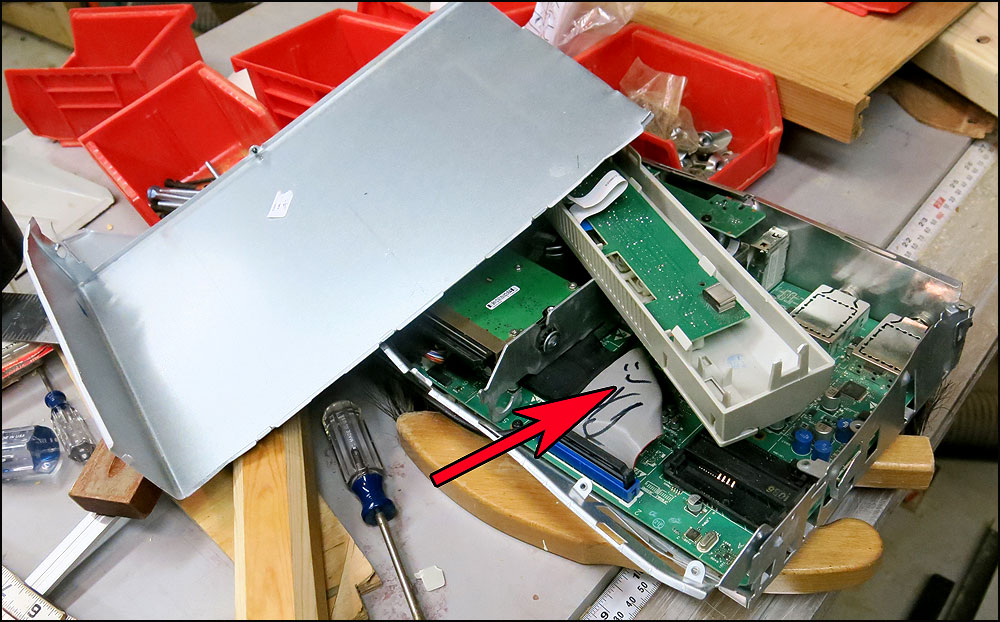

Using scaled photos I took before I mailed the lights off to Ireland, I knew I needed a post, the same diameter as the seat tube, and some metal strips. 1/8 steel stock I had was too thick, so I ‘re-purposed’ the lid of an old DirecTV box.

Hope they don’t want it back. Whoever made the thing must have been having a ‘Happy Day’ as you can see from the smiley face they drew on the wiring strap!!

Next was a piece of a 27mm ‘seat tube’ for the bracket. Not having a spare seat tube, I turned a 27mm dowel on the lathe.

In order for the light to hang vertical the bracket had to mimic the 72 degree back facing angle of the seat tube. Everything went together and am now just waiting for the paint to dry . . .

Good thing I am retired!!!

But . . . some are not, and still busy but find time to be creative. With the cold below zero temps, emJay spent a couple of evenings designing and making this custom daisy patterned fleece cover up for our pup Daisy. Her ears are always the first thing to get cold . . . not any more!!!